|

| Hydraulic Lift in India |

The Principle of Hydraulic Lift in India: Hydraulic Lift have long been part of history since renaissance took over the world by storm. Mechanical engineering slowly developed making new innovations and technological superiorities found ide Suspended hydraulic lifts.

Direct acting hydraulic lift

A direct acting type runs on oil pressure compression. There is a vertical cylinder fixed in the basement floor which contains a shaft that slides up by oil pressure once Hydraulic Lift fluid is injected by a pump in the cylinder. A small opening in one end of the cylinder allows the hydraulic fluid to enter and it then makes the shaft move up and down accordingly. This shaft called a ram pushes and pulls up a cabin attached on it where people stand to move between different floors. As the fluid recedes back to the oil chamber, the ram makes a decent descent.

This lift type is basically meant for small buildings only because the reclining piston has to be installed vertically erect to push up the chair. This means a lot of space needs to be dug beneath the floor of movement. However, A too high building won’t make the lifting mechanism as a good option as the cylinder will need an unthinkable extended height and extra space beneath the earth to make up for that height space. Still, this lift is thoughtfully safe and efficacious.

Suspended Hydraulic Lift: Quite similar to hydraulic goods lift manufacturers mechanism, the suspended one is elevated by pressured liquid that moves the sliding ram of a shaft attached to a set of pulley blocks. The passenger cabin is suspended from a wire cable, and a jigger attached to the ram and the set of two pulley blocks where one end is attached to the ram’s head and other is fixed to the shaft end. The ram ejects out of the shaft as oil compression forces it to expand thereby forcing the wire cable to stretch making the cage attached from the wire cable to elevate. The jigger elevates and descends the lift. The forceful pressure of liquid is the main functionary that elevates the cabin up because it pushes the sliding ram to move towards the left side. The movement of the sliding ram expands the distance between the fixed and movable pulleys and the cage is lifted up. As the fluid under inside the cylinder is released back, the pulleys retract and the cage comes down. This lifting mechanism is popular as there is no equal depth to height ratio required. These systems are economically viable.

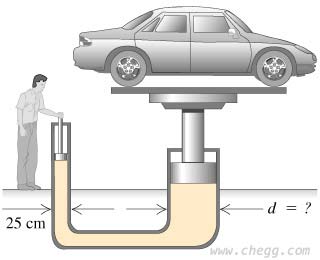

For industrial applications where low height lifting is required, a hydraulic scissor lift table helps raise or lower goods and/or persons. Lift tables help raise large, heavy loads through petty distance. A hydraulic lift working model can be deemed plausible to display various lifting mechanisms. Similarly hydraulic lift good manufacturers elevates with the help of plungers and there is an above ground fluid tank to eject the cabin by pistons. It is meant for small factory loads and building work. Scissor lift tablets can also be compared to Hydraulic car lifts. Most commonly installed in service stations, the hydraulic car lift makes easy elevation for Hydraulic carservicing and overhauling.

Common to all, these lifts employ hydraulics as their main force. Hydraulic lifts are used literally everywhere i.e. in hospitals, commercial places, hotels, homes, etc. Because without hydraulics lifts, the world would become slower. When safety is concerned, hydraulics are the savior of today and tomorrow.

for more information about Hydraulic Lifts, services and hydraulic goods lift manufacturers in India just visit on http://apexelevators.com/

Comments

Post a Comment